Steel Gate valves

Cast Steel Wedge Gate Valve Specifications

* Gate Valve Design:

API 600: Bolted Bonnet Steel Gate Valve for Petroleum and Natural Gas Industries

BS 1414: Specification for Steel Wedge Gate Valves (Flanged and Butt-welding Ends) for the Petroleum, Petrochemical and Allied Industries

DIN3352: Bolted Bonnet Steel Gate Valve for Petroleum and Natural Gas Industries

* Connection:

ASME B16.34 Valves Flanged, Threaded and Welding Ends

Flange: ASME B16.5 Pipe Flanges and Flanged Fittings: NPS 1/2 through 24

ASME B16.47 Series A Large Diameter Steel Flanges: NPS 26 Through NPS 60 Metric/Inch Standard

Butt Weld:ASME B16.25 Buttwelding Ends

* Face to face: ASME B16.10 Face to Face and End to End Dimensions of Valves

* MSS SP-25 Standard Marking System for Valves, Fittings, Flanges and Unions

* BB, OS&Y: Bolt Bonnet, Outside screw and Yoke

* Size Range: 2inch -- 40inch / DN50-- DN1000

* Pressure rating: ANSI Class150LB-- 2500LB / PN16-- PN100

* Materials:

Carbon Steel: ASTM A105, ASTM A216 WCB, ASTM A217 WC6, ASTM A217 WC9, ASTM A217 C5,ASTM A217 C12, ASTM A217 C12A

Stainless Steel: ASTM A351 CF8, ASTM A351 CF8M, ASTM A351 CF3, ASTM A351 CF3M, ASTM A351 CM8, ASTM A890 GR4A, ASTM A890 GR6A

* Operation: Handwheel, Gearbox, Electric actuator, Pneumatic actuator, hydraulica actuator

* Gate Valve Test: API598.

* Report: CHEMICAL ANALYSIS OF MATERIAL CERTIFAICATE EN 10204 3.1B

|

|

View Steel Gate valve with PDF

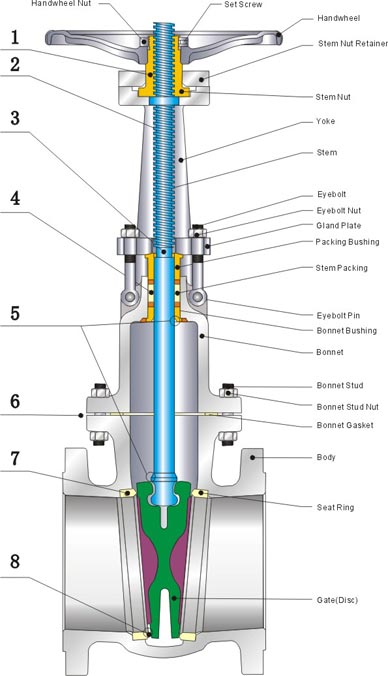

1 - Gate valve Stem Nut, replaceable in line.

2 - Steel Gate valve Rising stem with precision ASME double thread for quick operation.

3 - Stem-Gate connection designed so that under severe applied loads(stuck gate), the stem will fail outside of the stuffing box pressure boundry.

4 - Stem Packing is designed for optimum control of fugitive emissions leakage to the atmosphere. The ultra-low emission leakage rate is assured by the fine finish on the stem sealing area, the reduced diametrical clearances and the stem straightness control.

5 - Backseat, designed to relieve back pressure on the stem packing when fully seated. Replacing stem packing under pressure is not recommended.

6 - Body to Bonnet joint designed to apply a uniform load to the gasket to assure a leak proof seal.

7 - Steel Gate valve Seat rings are seal welded to provide a bubble tight joint.

8 - Stellited Seat Rings provide increased resistance to wear, abrasion and erosion of the sealing surfaces.