Cast Steel Gate valves

| Applicable standards: Design description: |

Gate Valve Series

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar. The gate faces can form a wedge shape or they can be parallel. Typical gate valves should never be used for regulating flow, unless they are specifically designed for that purpose. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening.

Cast Steel Wedge Gate Valve Specifications

* Design:

API 600: Bolted Bonnet Steel Gate Valve for Petroleum and Natural Gas Industries

BS 1414: Specification for Steel Wedge Gate Valves (Flanged and Butt-welding Ends) for the Petroleum, Petrochemical and Allied Industries

DIN3352: Bolted Bonnet Steel Gate Valve for Petroleum and Natural Gas Industries

* Connection: ASME B16.34 Valves Flanged, Threaded and Welding Ends

Flange: ASME B16.5 Pipe Flanges and Flanged Fittings: NPS 1/2 through 24

ASME B16.47 Series A Large Diameter Steel Flanges: NPS 26 Through NPS 60 Metric/Inch Standard

Butt Weld: ASME B16.25 Buttwelding Ends

* Face to face: ASME B16.10 Face to Face and End to End Dimensions of Valves

* MSS SP-25 Standard Marking System for Valves, Fittings, Flanges and Unions

* BB, OS&Y: Bolt Bonnet, Outside screw and Yoke

* Size Range: 2inch -- 40inch / DN50-- DN1000

* Pressure rating: ANSI Class150LB-- 2500LB / PN16-- PN100

* Materials:

Carbon Steel: ASTM A105, ASTM A216 WCB, ASTM A217 WC6, ASTM A217 WC9, ASTM A217 C5,ASTM A217 C12, ASTM A217 C12A

Stainless Steel: ASTM A351 CF8, ASTM A351 CF8M, ASTM A351 CF3, ASTM A351 CF3M, ASTM A351 CM8, ASTM A890 GR4A, ASTM A890 GR6A

* Operation: Handwheel, Gearbox, Electric actuator, Pneumatic actuator, hydraulica actuator

* Test: API598.

* Report: CHEMICAL ANALYSIS OF MATERIAL CERTIFAICATE EN 10204 3.1B

View Cast Steel Gate valve with PDF

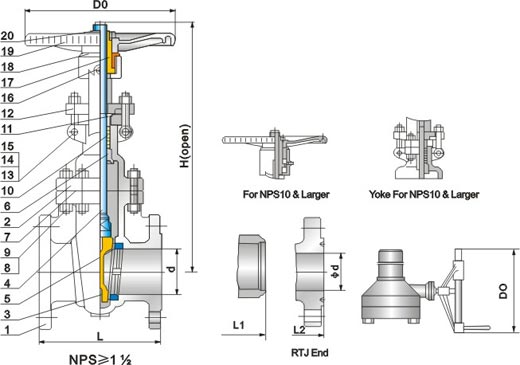

Cast steel Gate valve Parts and Material List

| Parts No. | Parts Name | Materials | ||||

| WCB/Trim1 | WCB/Trim5 | WCB/Trim8 | CF8/304 | CF8M/316 | ||

| 1 | Body | ASTM A216 WCB | ASTM A351 CF8 | ASTM A351 CF8M | ||

| 2 | Gasket | Soft iron+Graphite or 304+Graphite | 304+Graphite | 316+Graphite | ||

| 3 | Seat ring | A105+13Cr | A105+STL | A105+STL | ASTM A351 CF8 | ASTM A351 CF8M |

| 4 | Gate | ASTM A216 WCB+13Cr | ASTM A216WCB+STL | ASTM A216 WCB+13Cr | ASTM A351 CF8 | ASTM A351 CF8M |

| 5 | Stem | ASTM A182 F6a | ASTM A182 F304 | AST A182 F316 | ||

| 6 | Backseat bushing | ASTM A182 F6a | ASTM A351 CF8 | ASTM A351 CF8M | ||

| 7 | Packing | Graphite | Graphite | Graphite | ||

| 8 | Gland | ASTM A182 F6a | ASTM A182 F304 | ASTM A182 F316 | ||

| 9 | Gland eyebolt | ASTM A193 B7 | ASTM A193 B8 | ASTM A193 B8M | ||

| 10 | Eyebolt nut | ASTM A194 2H | ASTM A193 8 | ASTM A194 8M | ||

| 11 | Eyebolt pin | ASTM A36 | 304SS | 316ss | ||

| 12 | Gland flange | ASTM A216 WCB | ASTM A351 CF8 | ASTM A351 CF8M | ||

| 13 | Bonnet bolt | AST A193 B7 | ASTM A193 B8 | ASTM A193 B8M | ||

| 14 | Bonnet nut | ASTM A194 2H | ASTM A194 8 | ASTM A194 8M | ||

| 15 | Bonnet | ASTM A216 WCB | ASTM A351 CF8 | ASTM A351 CF8M | ||

| 16 | Nipple | Carbon steel | Carbon steel | Carbon steel | ||

| 17 | Stem nut | ASTM A439 D2 | ASTM A439 D2 | ASTM A439 D2 | ||

| 18 | Yoke sleeve nut | Carbon steel | Carbon steel | Carbon steel | ||

| 19 | Hand wheel | Ductile iron | Ductile iron | Ductile iron | ||

| 20 | Hand wheelnut | Carbon steel | Carbon steel | Carbon steel | ||

| 21 | Set screw | ASTM A193 B7 | ASTM A193 B7 | ASTM A193 B7 | ||

NOTE: The chart above only lists out some common composition of steel check valve parts. We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Gate valve Structure dimensions

| CLASS/SIZE | 150 -L | 300 -L | 600 -L | 900-L | ||||

| RF | BW | RF/BW | RTJ | RF/BW | RTJ | RF/BW | RTJ | |

| 2 | 178 | 216 | 216 | 232 | 292 | 295 | 368 | 371 |

| 2 1/2 | 191 | 241 | 241 | 257 | 330 | 333 | 419 | 422 |

| 3 | 203 | 283 | 283 | 298 | 356 | 359 | 381 | 384 |

| 4 | 229 | 305 | 305 | 321 | 432 | 435 | 457 | 460 |

| 5 | 254 | 381 | 381 | 397 | 508 | 511 | 559 | 562 |

| 6 | 267 | 403 | 403 | 419 | 559 | 562 | 610 | 613 |

| 8 | 292 | 419 | 419 | 435 | 660 | 664 | 737 | 740 |

| 10 | 330 | 457 | 457 | 473 | 787 | 791 | 838 | 841 |

| 12 | 356 | 502 | 502 | 518 | 838 | 841 | 965 | 968 |

| 14 | 381 | 572 | 762 | 778 | 889 | 892 | 1029 | 1038 |

| 16 | 406 | 610 | 838 | 854 | 991 | 994 | 1130 | 1140 |

| 18 | 432 | 660 | 914 | 930 | 1092 | 1095 | ||

| 20 | 457 | 711 | 991 | 1010 | 1194 | 1200 | ||

| 24 | 508 | 813 | 1143 | 1165 | 1397 | 1407 | ||

| 26 | 559 | 864 | 1245 | 1270 | ||||

| 28 | 610 | 914 | 1346 | 1372 | ||||

| 30 | 610 | 914 | 1397 | 1422 | ||||

| 32 | 711 | 965 | 1524 | 1553 | ||||

| 34 | 762 | 1016 | 1626 | 1654 | ||||

| 36 | 711 | 1016 | 1727 | 1756 | ||||

1. Gate valve are normally used for on-off service and are not recommended for throttling service.

2. Gate valves are normally installed in horizontal pipe runs with the stem vertical. They can also be installed in vertical or horizontal pipe runs with the stem other than vertical, but may require special construction depending on valve size, service conditions and materials. WHEN PURCHASING VALVES FOR OTHER THAN NORMAL INSTALLATION, THE VALVE ORIENTATION SHOULD BE SPECIFIED.

3. Flexible or split wedges are recommended for service above 500 ℉ to avoid wedge binding due to thermal expansion. This may occur if the valve is closed when cold, and then heated to operating temperature.

4. Threaded seat rings should be lock welded to the body when used in high velocity (turbulent) or thermal cycling services to avoid loosening. Please specify.

5. After closing a gate valve with sufficient force to develop shutoff, the stem should be backed off slightly (1/8 to 1/4 turn) to relieve stem load. This will enable the stem to expand slightly without binding or damaging the valve and will not affect shutoff.