Class150 Gate valves

| Applicable standards: Design description:

|

Gate Valve Series

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar. The gate faces can form a wedge shape or they can be parallel. Typical gate valves should never be used for regulating flow, unless they are specifically designed for that purpose. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed. When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

Gate Valve Design Feature:

·Meet design requirements of ANSI B16.5, B16.34, B16.10 ,B16.25 (for NPS≤24), MSS SP-44(for NPS>24), API-600 or API 6D

·Inspection and Test: accord with API 598

·Full range of body/bonnet & trim materials

·Choice of solid, flex or split wedge design

·Back seating design

·Upset forged T-head stem design

·OS&Y construction

·Renewable seat rings--seal welded

·Full port design

·Full length wedge guides

·Optional impact hand wheel

·Optional lengthen stem

Gate Valve Products Range:

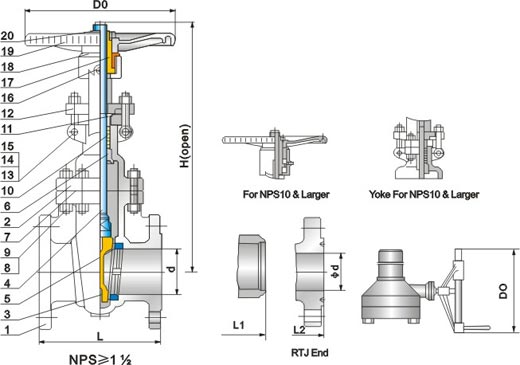

Size: 2"~48"

Rating: ANSI Class 150LB-2500LB

Materials : WCB,LCB,CF8,CF8M,CF3,CF3M,WC6,WC9, C5,C12 or Equivalent.

Actuation: Handwheel, Gear, Motor, Pneumatic

View 150Lb Gate valve with PDF

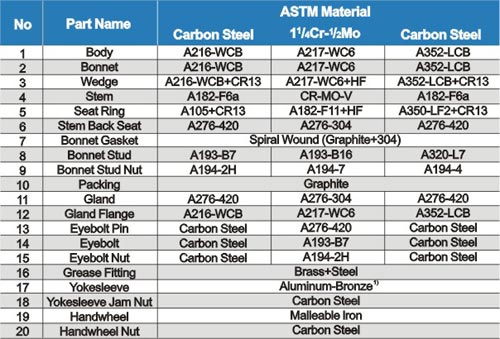

150Lb Gate valve Materials of parts

Note: 1).Ductile Ni-Resist optional

2).Wedge and seat ring may either be solid facing material or a base material equal to or better than the body/bonnet material with facing as shown.

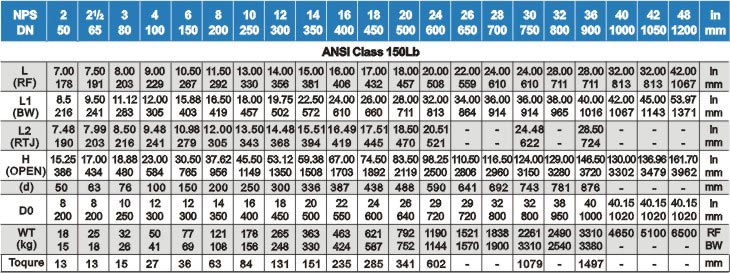

Class150 Gate valve Dimensions data