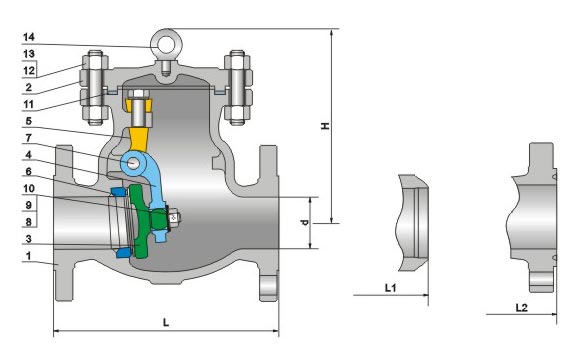

Check Valve Series

A check valve allows fluid to flow through it in only one direction. Check valves are two-port valves, meaning they have two openings in the body, one for fluid to enter and the other for fluid to leave. There are various types of check valves used in a wide variety of applications. Although they are available in a wide range of sizes and costs, check valves generally are very small, simple, and/or cheap. Check valves work automatically and most are not controlled by a person or any external control; accordingly, most do not have any valve handle or stem. WENZHOU WINDMILL VALVE CO.,LTD. http://www.dfcvalve.com .

Check Valve Series Design Features

Seat

For cast steel check valve, the seat material is usually forged steel. The sealing surface of the seat is spray welded with hard alloy specified by the customer. Renewable threaded seat is used for NPS≤10 check valves, and welded-on seat is optional. Welded-on seat is used for NPS≥12 carbon steel gate valves. For stainless steel check valve, integral seat is usually applied, or to weld hard alloy directly integrally. Threaded-in or welded-on seat is also optional for stainless steel check valve if required.

Body-Bonnet Gasket

Stainless steel + flexible graphite wounded gasket is used for Class150 and Class 300 check valve; stainless steel flexible graphite wounded gasket is used for Class 600 check valve, ring type joint gasket is used for Class 900 check valve; pressure seal design is used for Class1500 to Class 2500 check valve.

Body-Bonnet Connection

The body and bonnet of Class150 to Class 900 check valves are usually with studs and nuts. And the body and bonnet of Class 1500 to Class 2500 check valves are usually of pressure seal design.