Trunnion ball valves

WINDMILL VALVE Manufacturer of Trunnion ball valve from Wenzhou, Trunnion ball valves are suitable for use on various kinds of pipelines of Class 150~Class 2500, PN16~PN160, JIS10K~JIS20K to cut off or turn on the pipeline medium, of which the operation types include worm gear. manual, pneumatic or electric actuators, being in general of flange connection, and butt welding ends connection as well.

| Trunnion ball valve 's PDF file |

Trunnion ball valve Application:

can be used in long distance pipeline of large diameter, high pressure fixed ball valve, widely used in chemical, petrochemical and oil and gas industry.

● two type and three type valve

● The seat structure: * single sealing system, since the pressure relief valve

● The range of temperature: -29 ℃ ~ 429 ℃

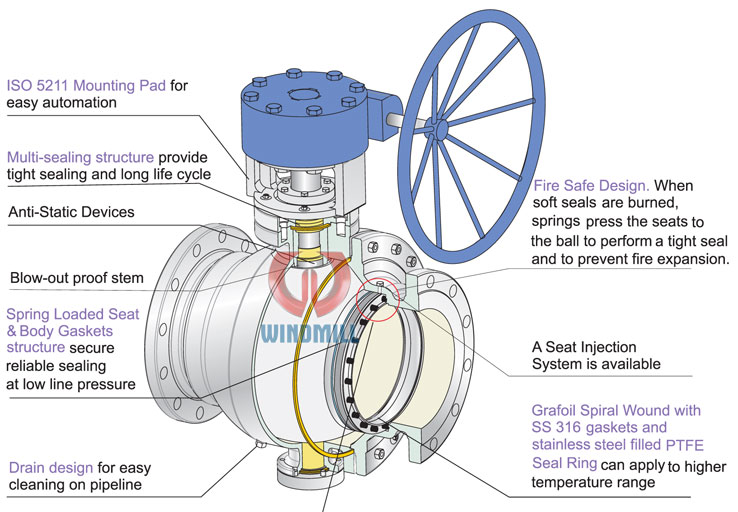

Design features of trunnion ball valve

Urgent Grease Injection Device

According to customers' requirement, the trunnion ball valves made by WINDMILL company are provided with devices for urgent grease injection, which are on both the stem and seat for the trunnion ball valves of DN> 150mm(NPS6), and in the body cavity for the valve of DN< 125mm. When the O ring of stem or the body seat ring is damaged due to acrident, the medium leakage between body and stem can be prevented by injecting the sealing grease through the device.

Double-block And Bleed Functions

In general, WINDMILL's trunnion ball valve features the front ball seating design structure. Each seat of the ball valve can separately cut off the medium at both inlet and outlet of the valve to realize double block functions. When the ball valve is closed, body cavity and two of the body ends can be blocked with each other even if both the inlet and outlet are under pressure, when the medium left in the body cavity might be bled through the relief valve.

Fire Safe Design

With the ball valve heated in a fire application, the non-metal material parts such as seat sealing ring of PTFE, O ring for the stem, and sealing gasket for body and bonnet, might he damaged due to high temperature .WINDMILL's special design of auxiliary metal to metal or the graphite seal is provited for the trunnion ball valve to effectively prevent both internal and external leakage of the valve. As required by customers, WINDMILL's fire safe design for the trunnion ball valve meets the requirement of API 607. API 6Fa, BS 6755.

trunnion ball valve http://www.dfcvalve.com/